Denmark KOGE Thermal Power Station Project

Project name: Denmark KOGE Thermal Station

Equipment selection: 1 unit 12MW LiBr Absorption Heat Pump

General introduction

Project Overview: Denmark Koge Thermal Power Station

Project Name: Koge Thermal Power Station Heating System Upgrade

Location: Koge, Denmark

Industry: Thermal Power Generation

Heating Grid: Copenhagen Urban Heat Grid

Fuel Source: Biomass (including sawdust and other biomass materials)

Project Details:

The Koge Thermal Power Station is a significant energy facility in Denmark, utilizing biomass incineration to generate both heating and electricity for the surrounding area. The station burns various types of biomass, including sawdust, to provide district heating and power to the city, playing a key role in Denmark's commitment to renewable energy and carbon reduction.

Objective:

In 2020, the station initiated a project to enhance its heating efficiency and capacity by implementing a new exhaust condensing heat recovery system combined with LiBr absorption heat pumps provided by Hope Deepblue. The key goals of this project are:

- Recover waste heat: Efficiently utilize exhaust heat from the biomass incineration process.

- Increase heating output: Enhance the station's capacity to supply heat to the Copenhagen urban heat grid.

- Improve energy efficiency: Optimize the heat recovery process to reduce energy waste and improve overall system efficiency.

System Components:

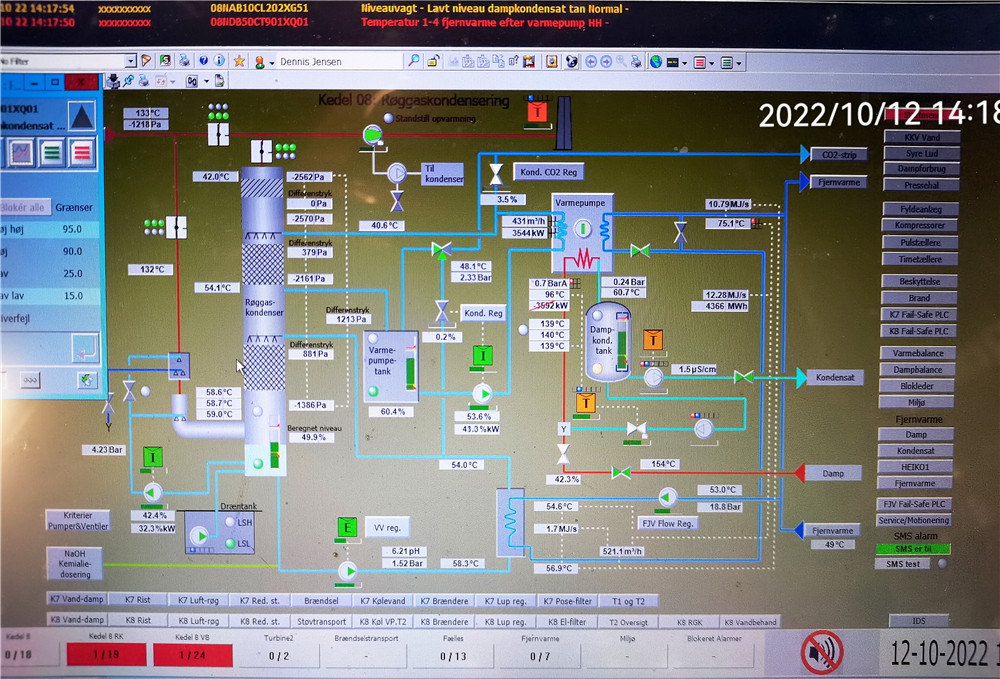

- Exhaust Condensing Heat Recovery System:

- This system is designed to capture and recover waste heat from the exhaust gases generated during the biomass incineration process.

- The recovered heat is typically used to pre-heat water, which improves the efficiency of the heat pump and reduces the energy required to achieve the desired temperature.

- LiBr Absorption Heat Pumps:

- LiBr (Lithium Bromide) absorption heat pumps are used to further enhance the efficiency of the heating process by extracting additional heat from the recovered exhaust.

- These heat pumps operate on the principle of absorption refrigeration, utilizing the thermal energy from exhaust gases to provide heating.

- The heat pumps significantly improve heat recovery, increasing the capacity of the thermal power station to deliver heating to the city.

Benefits of the System:

- Improved Efficiency: The integration of the exhaust heat recovery system and absorption heat pumps allows the station to recycle waste heat, improving overall efficiency.

- Increased Heating Capacity: By using the recovered heat, the system increases the amount of heating that can be delivered to the urban district, thereby supporting the Copenhagen heat grid.

- Environmental Impact: The efficient use of biomass as a renewable energy source and the reduction of waste heat help lower the carbon footprint of the station.

- Cost Savings: Reducing the need for additional energy inputs to generate heat lowers operational costs for the station, improving the economic viability of the project.

Implementation Plan:

- System Design: The design of the heat recovery and heat pump system is customized to meet the specific needs of the Koge Thermal Power Station, taking into account the biomass incineration process and the requirements of the Copenhagen heating grid.

- Integration: The system will be integrated into the existing infrastructure of the station, with minimal disruption to the ongoing operations of the power generation and heating processes.

- Operational Timeline: The project is expected to significantly improve the station's heating capacity and efficiency within the first year of operation.

Long-term Impact:

This project aligns with Denmark's broader sustainability goals, contributing to the country's transition to renewable energy and enhancing the resilience of urban heating systems. The success of this system can also serve as a model for other countries looking to improve the efficiency of thermal power stations and district heating networks.

Technical Data

Heating capacity: 12MW/unit

Driven steam pressure: 0.3MPa(G)

Qty: 1 unit

COP: approx 1.7

District heating water: 60.5°C /76.8°C

Dimension: 9300*3100*5350mm

Transportation weight: 65.4t/unit

Profibus-DP

Steam consumption: 1.562 -2.872kg/s

Chilled water :37°C/27°C

Web: https://www.deepbluechiller.com/

E-Mail: yut@dlhope.com / young@dlhope.com

Mob: +86 15882434819/+86 15680009866

Post time: Mar-31-2023