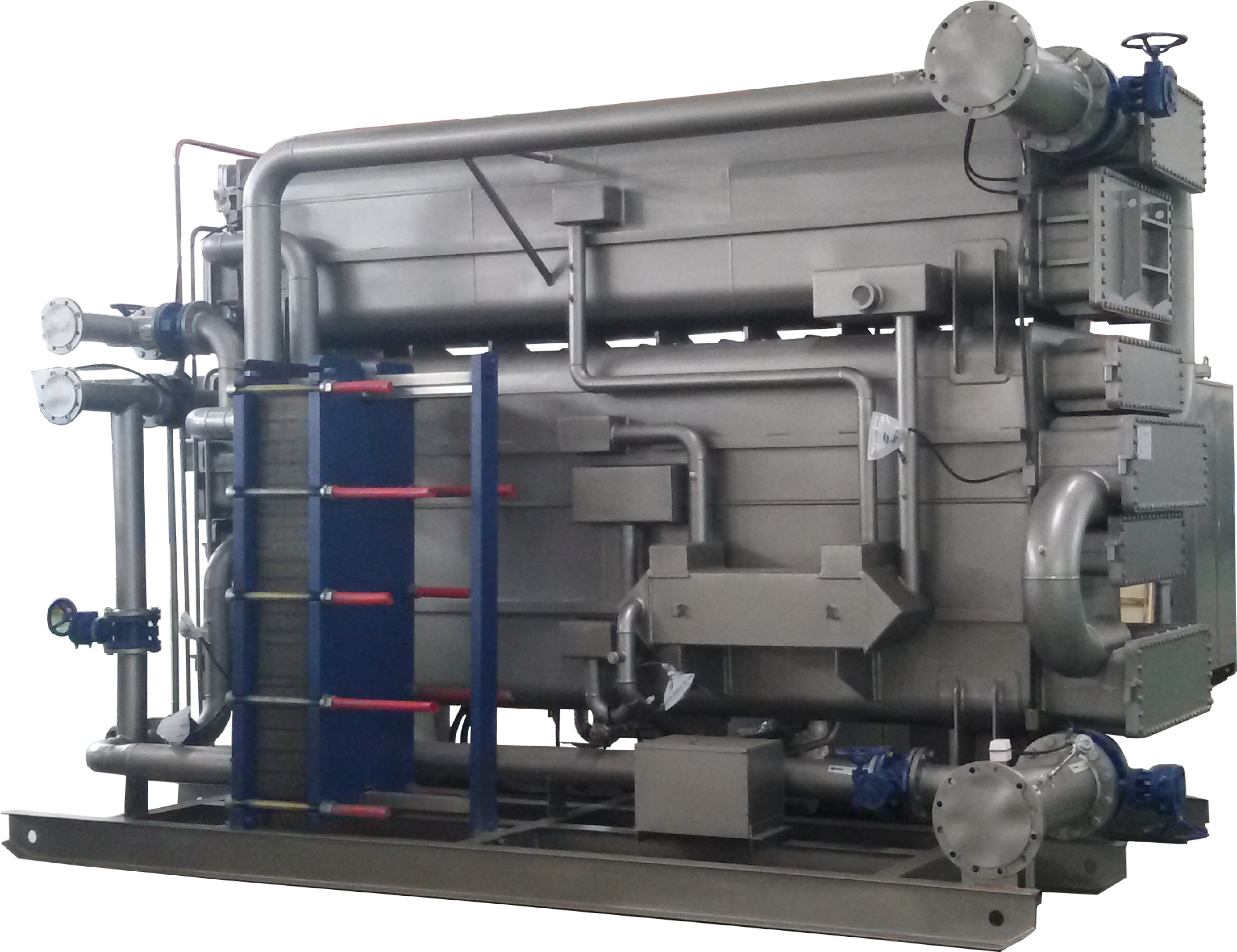

Tube Broken Alarm System

The tube broken alarm system for LiBr absorption units is an important safety protection mechanism designed to detect and prevent internal tube broken or leakage in real time. Through this system, potential pipe failures can be detected in time to prevent damage to equipment and the environment from refrigerant water leakage, and to avoid system failures and safety hazards caused by tube broken.

The alarm system mainly monitors and protects through the following aspects:

1. Pressure Monitoring

Deepblue's LiBr absorption chiller or heat pump are equipped with pressure sensors and other relevant instruments for detecting the internal pressure status of the unit. When the unit is operating normally, the pressure inside the pipeline should be maintained within a predetermined range. If there is a broken or leakage in the pipeline, the pressure will drop drastically. The pressure sensor can detect this change in real time and transmit the signal to the control center. Once abnormal pressure is detected, the system will automatically trigger an alarm to remind the operator to check the pipeline status.

2. Flow Monitoring

The flow sensor is another key component. It monitors real-time changes in refrigerant water flow. When there is a tube broken or leakage, the flow rate will fluctuate or drop significantly. By comparing the actual flow rate with a preset threshold, the system quickly detects abnormal flow rates and sends out an alarm to notify equipment maintenance personnel to take action in a timely manner.

3. Temperature Monitoring

When piping leakage occurs, especially gas or refrigerant leakage, the fluid temperature may fluctuate abnormally. Through the set temperature sensors of the unit, these temperature sensors will detect these changes and feed the information to the alarm system. When the temperature is out of the set range, the system will automatically start the alarm program.

4. Automatic Emergency Response

Once the system detects a tube broken or leakage, the alarm system will automatically implement emergency response measures, including closing the relevant valves, stopping the flow of refrigerant water, cutting off the power supply or starting a backup system. These automatic response measures can not only quickly control the leakage, but also prevent further damage to the equipment or extend the danger.

5. Alarm Signal and Notification

When the tube broken and the liquid level in the unit rises, the unit alarm system is triggered. At the same time, the system will notify the operator through the control system and supports remote notification to management. Ensure that the operator get the alarm at the first time and act quickly.

6.Physical Pressure Relief

LiBr units are equipped with a removable rupture disk to physically protect the unit. If the pressure inside the unit rises sharply, it will be relieved by the rupture disk.

Hope Deepblue's LiBr absorption units have a tube broken alarm system that can detect pipeline failures in time and avoid equipment damage and environmental pollution through alarms and automatic emergency response measures by real-time monitoring of pipeline pressure, flow and temperature. Through this system, the equipment is able to respond quickly when problems occur, which not only improves safety, but also reduces the risk of malfunctions and maintenance costs.

Post time: Mar-14-2025