Quality Over Quantity - The Slogan of Hope Deepblue Absorption Unit

2005 indeed feels like a long time ago, marked by significant milestones in various fields. The opening of the Qinghai-Tibet Railway, which connected Lhasa to the rest of China, and the launch of Hong Kong Disneyland were major events in infrastructure and entertainment. On the technological front, the A380's debut and Seoul's renaming as the capital were both symbolic of progress and change.

For Hope Deepblue, 2005 was a noteworthy year as well, with the successful delivery and commissioning of the direct-fired LiBr Absorption Chiller at Dongfang Red Square in Yinchuan. This event marked a key achievement in the company's history, as it signified the beginning of successful operations for one of its major projects. The smooth commissioning and subsequent operation set a precedent for future successes and helped solidify Hope Deepblue's reputation in the field of energy efficiency and heat pump technology. It was a moment of pride for the company, contributing to its legacy of innovation and commitment to providing quality, reliable solutions.

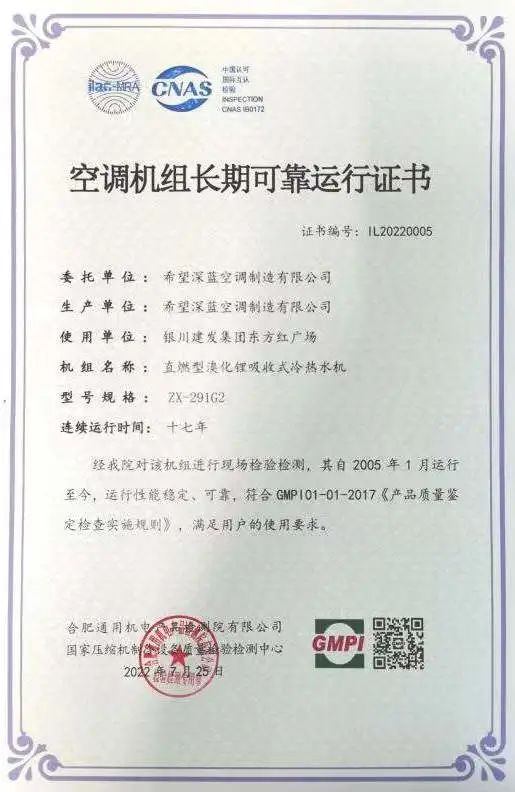

Seventeen years after its successful commissioning in 2005, the direct combustion units installed at Dongfang Hong Square in Yinchuan continue to demonstrate exceptional performance. In 2022, the Hefei General Mechanical and Electrical Products Testing Institute, a leading authority in the refrigeration and air conditioning industry, conducted a thorough on-site inspection of these units. After a detailed verification process and multiple evaluations, Hefei Institute awarded Hope Deepblue with the prestigious "Certificate of Long-term Reliable Operation of Air Conditioning Unit."

This certification acknowledges the continued stable and reliable performance of the unit, which has been operating without interruption since its installation in January 2005. It highlights the unit's consistent ability to meet user requirements and comply with the stringent regulations and certification conditions. This recognition underscores Hope Deepblue’s commitment to providing high-quality, durable solutions and reaffirms the trust and satisfaction of its customers over the years.

The unit, purchased by Yinchuan Construction and Development Group in 2004 and installed in 2005, has proven to be a reliable workhorse over the years. Despite being in operation for more than a decade, the machine room remains as clean and bright as the day it was first set up. While no longer at the height of its initial glamour, the unit continues to efficiently provide both refrigeration and heating, quietly supporting the bustling activity of Dongfang Red Square shopping mall.

In fact, the enduring performance of the unit in the early years led China Development Group to continue choosing Hope Deepblue for other projects. Notably, in the development of the Modern City project—referred to as "the first floor of Ningxia" at the time—Hope Deepblue’s stable, reliable quality, combined with warm and thoughtful service, led to the continued purchase and use of their products. This long-lasting partnership is a testament to the trust and satisfaction Hope Deepblue has earned from its clients over the years.

The Jianfa Dongfanghong Square unit is just one example of the many "vintage" units from Hope Deepblue that have been providing stable service across China for many years. This longevity is not a matter of coincidence or luck; it is the result of a scientifically designed and well-implemented quality management system and standardized operations. Hope Deepblue has always placed a strong emphasis on quality management, making it a cornerstone of their operations.

The company has developed its own unique seven-step quality management method, ensuring that every product meets rigorous standards from design through to service. This systematic approach to quality is what has enabled Hope Deepblue to maintain its reputation for reliability, delivering products that stand the test of time while continuously meeting the needs of their customers.

First and foremost, quality is not just about production or inspection by the quality management department; it requires full involvement at every stage and must be integrated throughout the entire process. From the initial product design to the selection of materials and components, through production and inspection, and extending to after-sales service, quality management spans the entire product lifecycle.

Secondly, Hope Deepblue ensures that the main materials and components are sourced from well-known international and domestic brands, guaranteeing the quality of the final products from the very beginning. The company has implemented a dedicated supplier management system, where qualified suppliers are assessed annually. Even those deemed qualified can face elimination if they do not meet the high standards of excellence Hope Deepblue expects.

Thirdly, all materials and components undergo rigorous inspection at Hope Deepblue, even if they have already been checked by the supplier. Despite the supplier’s inspections, Hope Deepblue invests heavily in professional testing equipment to perform in-house quality checks. This ensures that only materials meeting the company’s strict standards are accepted and used in production.

Fourthly, every part is manufactured according to the production process, with strict control over key processes. Each step is documented with quality tracking and inspection records. Hope Deepblue has introduced advanced instruments and scientific methods to ensure the accuracy of testing. For instance, the vacuum degree test uses the most advanced German units and applies the strictest leakage rate standards, which are over four orders of magnitude stricter than the national standard.

Fifthly, Hope Deepblue invests heavily in testing and adheres to a practice of inspecting the completion of each unit before delivery. This practice has been in place for over 20 years. The company has established a leading product testing center in the industry, where customers can visit the factory and personally witness the final stages of product completion.

Sixthly, while the quality manager is not a senior executive, Hope Deepblue gives them the highest authority to veto any quality issues. This ensures that quality remains the top priority in all decisions related to production and delivery.

Seventhly, the quality management mechanism ensures that if any issues arise with a unit, whether after ten years or at the end of its life cycle, the problem can be traced back to its source, and the responsible individual can be identified. This accountability structure encourages everyone at Hope Deepblue to remain vigilant and conscientious about quality.

Quality is gold! Like gold, quality is rare and precious. There is no shortcut to quality management. Hope Deepblue is committed to the pragmatic principle of "Quality first, customer first," and is dedicated to strengthening the execution of this principle. The year 2022 marks the "first year" of Hope Deepblue's focus on quality, but the journey toward continuous quality improvement is ongoing and will never cease.

Web: https://www.deepbluechiller.com/

E-Mail: yut@dlhope.com / young@dlhope.com

Mob: +86 15882434819/+86 15680009866

Post time: Mar-30-2023