LiBr Absorption Heat Pump Installed in Sappi Paper-making Factory

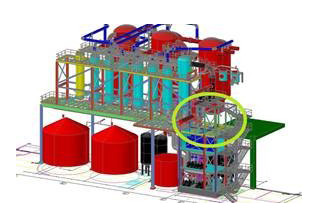

The successful delivery of a large steam LiBr absorption heat pump from Hope Deepblue's factory to Austria highlights the company's ability to meet complex project requirements, particularly when space limitations and transportation constraints are involved. Due to the dimensions of the heat pump and the constraints of the machine room, a split delivery approach was chosen for this project.

This method involves dividing the heat pump into several parts for easier transportation, ensuring that all components can be shipped efficiently and without exceeding transport limitations. Once the parts arrive in Austria, they will be assembled on-site, allowing the system to be integrated and set up for operation.

This approach demonstrates Hope Deepblue’s flexibility and capability in managing large-scale projects, ensuring that the heat pump system can be installed and fully operational despite logistical challenges. The modular delivery and assembly process also ensure that the system can be customized to fit the specific requirements of the site, optimizing the heat pump’s performance once installed.

Hope Deepblue’s ability to handle complex installations, including split deliveries and on-site assembly, reinforces its reputation as a leader in advanced energy-saving solutions, such as waste heat recovery systems and LiBr absorption heat pumps. The successful installation of this unit in Austria will contribute to the company’s growing global footprint in sustainable energy technologies.

Sappi Group, a renowned paper manufacturing company in Europe, is the customer for this project. Established in 1936, the company has over 80 years of development history and has grown into a global leader in providing dissolved pulp, pulp, and paper products to customers in 150 countries. With production facilities spread across Western Europe, the steam absorption heat pump exported for this project will be installed at their Austrian factory to enhance energy efficiency and heat recovery. Known for their stringent quality and functional requirements, Sappi Group presents a high level of challenge, especially in the German-speaking region, making it difficult to secure and complete the order. However, with strong leadership and the dedicated efforts of the entire team, along with overcoming challenges in technical design, process manufacturing, and meeting strict quality standards, the production and delivery were successfully completed.

Based in China and serving the world, Hope Deepblue has made continuous efforts to expand its overseas presence and achieve remarkable success in the European market. Among its notable clients in the industry are ENI Oil Group (a top 500 company), the Danieli Group, Aircraft European Manufacturing Base, and Ferrari. In the municipal sector, Hope Deepblue's LiBr absorption chillers and heat pumps have been deployed in various demonstration projects, such as the direct-fired absorption heat pump at Potonsie Hospital in Paris, the steam absorption chiller at Gemini Pope’s Hospital in Rome, the hot water absorption chiller at Rome Central Railway Station, and the steam absorption heat pump at Copenhagen Heating Station. From "Made-in-China" to "Intelligence from China," Hope Deepblue has made significant strides in delivering high-quality, efficient solutions, earning recognition as a trusted Chinese brand on the global stage.

Web: https://www.deepbluechiller.com/

E-Mail: yut@dlhope.com / young@dlhope.com

Mob: +86 15882434819/+86 15680009866

Post time: Mar-30-2023