Absorption Chillers Benefits Liquor Brewing, Hope Deepblue Service Improves Satisfaction

The Wuyou Group Distillery, located in the heart of Maotai Town in Guizhou Province, is deeply rooted in the traditional methods of liquor brewing. Maotai liquor, one of China’s most famous and revered spirits, has a long history, and the distillery follows the Maotai brewing standard to ensure high-quality production.

The decision to begin brewing at 4 a.m. is tied to several factors. The cooler, early morning temperatures are ideal for the delicate fermentation process required in Maotai production. The cooler air enhances the overall brewing environment, reducing the risk of overheating that could affect the fermentation process and, ultimately, the quality of the liquor. Furthermore, the ambient temperature during this period helps regulate the production process, contributing to the consistency and excellence of the finished product.

Temperature is critical to brewing high-quality liquor, as it influences the fermentation and aging processes. The ideal temperature helps maintain the integrity of the fermentation environment, which is essential for producing the distinctive flavors and qualities associated with Maotai liquor. As such, controlling and optimizing the brewing environment is a key factor in ensuring that the final product meets the high standards that have made Maotai famous worldwide.

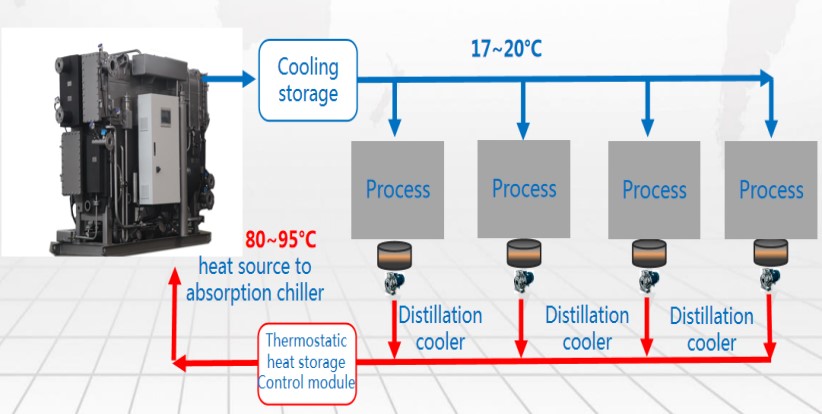

Hope Deepblue's solution for the Wuyou Group Distillery involves using a hot water absorption chiller to recycle the hot water produced during the distillation process. This innovative approach addresses the challenge of maintaining a continuous and effective cooling cycle during liquor production.

How the System Works:

- Distillation Process: The distillery uses low-temperature water for cooling the liquor steam during the brewing process. However, as the water is used, its temperature rises and it becomes less effective at cooling the steam.

- Recycling Hot Water: The heated water, which would otherwise lose its cooling efficiency, is then sent to a hot water LiBr absorption chiller. This chiller utilizes the thermal energy from the hot water to produce chilled water.

- Chilled Water for Liquor Cooling: The chilled water produced by the absorption chiller is then used to continue cooling the liquor steam, maintaining the necessary low temperatures for the distillation process.

This system ensures that the cooling process remains effective without the need for additional electrical energy, using thermal energy from the waste heat generated in the distillation process. By recycling the heat in this way, the distillery reduces energy consumption and enhances operational efficiency.

Benefits of the Solution:

- Energy Efficiency: The system significantly reduces energy consumption by utilizing waste heat to drive the chiller, which would otherwise be lost.

- Cost Savings: By recycling hot water, the distillery lowers its reliance on external cooling systems or additional energy sources, which leads to cost savings.

- Sustainability: This method supports the distillery’s sustainability efforts by reducing overall energy use and improving the efficiency of the brewing process, contributing to carbon reduction and better environmental management.

Hope Deepblue’s hot water absorption chiller helps optimize the distillation process, maintaining the necessary cooling conditions for high-quality liquor production while making full use of available thermal resources.

The project involving the use of LiBr absorption chillers in the liquor brewing industry marks a significant milestone for both Hope Deepblue and the industry in China. This is the first time LiBr absorption chillers have been applied to this field, underscoring Hope Deepblue's leadership in exploring innovative solutions for industrial waste heat utilization.

Key Aspects of the Project:

- First in the Industry: As part of this EPC project, Hope Deepblue is pioneering the use of LiBr absorption chillers in the liquor brewing industry in China. This innovation leverages waste heat from the distillation process to drive the chiller, optimizing energy use while ensuring efficient cooling for liquor production.

- Industrial Waste Heat Utilization: By utilizing waste heat from the brewing process, Hope Deepblue is contributing to a sustainable approach in the brewing industry. This system minimizes energy consumption by making use of excess thermal energy that would otherwise go to waste.

- Philosophy of Sustainability: Hope Deepblue’s commitment to sustainability is encapsulated in its philosophy, "Bluer Sky, Greener World". The adoption of LiBr absorption chillers in this industry reflects this core value, focusing on energy-saving and carbon reduction. By utilizing waste heat for cooling purposes, the project helps reduce the distillery's carbon footprint, contributing to a greener, more sustainable world.

- Tailored Solutions for Customers: Hope Deepblue continues to explore new applications for its technology, constantly seeking to meet the specific needs of its customers. In this case, by identifying an innovative solution for the liquor brewing industry, Hope Deepblue is able to provide a customized, energy-efficient solution that directly addresses the challenges faced by distilleries in maintaining consistent cooling conditions.

Conclusion:

Hope Deepblue’s involvement in the liquor brewing industry through the use of LiBr absorption chillers represents an important step towards energy efficiency and environmental sustainability in the industry. By utilizing waste heat and aligning with its philosophy of "Bluer Sky, Greener World," Hope Deepblue not only provides cutting-edge technology but also contributes to the broader goal of carbon reduction and sustainable industrial practices. This project serves as a model for future industrial applications, demonstrating the significant potential of waste heat utilization in diverse sectors.

Web: https://www.deepbluechiller.com/

E-Mail: yut@dlhope.com / young@dlhope.com

Mob: +86 15882434819/+86 15680009866

Post time: Jul-17-2023