Products

Multi Energy LiBr Absorption Chiller

Working principle

Using high-temperature flue gas and natural gas as the driving heat resource, the flue gas and direct-fired LiBr absorption chiller (The chiller/The unit) utilizes the refrigerant water’s evaporation to produce chilled water. In our daily life, as we all know, we will feel cool if dripping some alcohol on the skin; that’s because the evaporation absorbs heat from our skin. Not only alcohol, but all other kinds of liquid will absorb surrounding heat during evaporation. The lower the atmospheric pressure, the lower the vaporization temperature. For example, the water boiling point is 100℃ under 1 atmosphere of pressure, but if the atmospheric pressure drops to 0.00891, the water boiling point becomes 5℃. That’s why under vacuum conditions, water can vaporize at very low temperatures.

This is the basic working principle of a multi-energy LiBr absorption chiller. Water (refrigerant) vaporizes in the high-vacuum absorber and absorbs heat from the water to be cooled. The refrigerant vapor is then absorbed by the LiBr solution (absorbent) and circulated by pumps. The process repeats. In this process, water chiller manufacturers-Hope Deepblue play a key role in optimizing designs to ensure efficient heat exchange and absorption cycles.

Contact us for 100% customization.

Cooling cycle

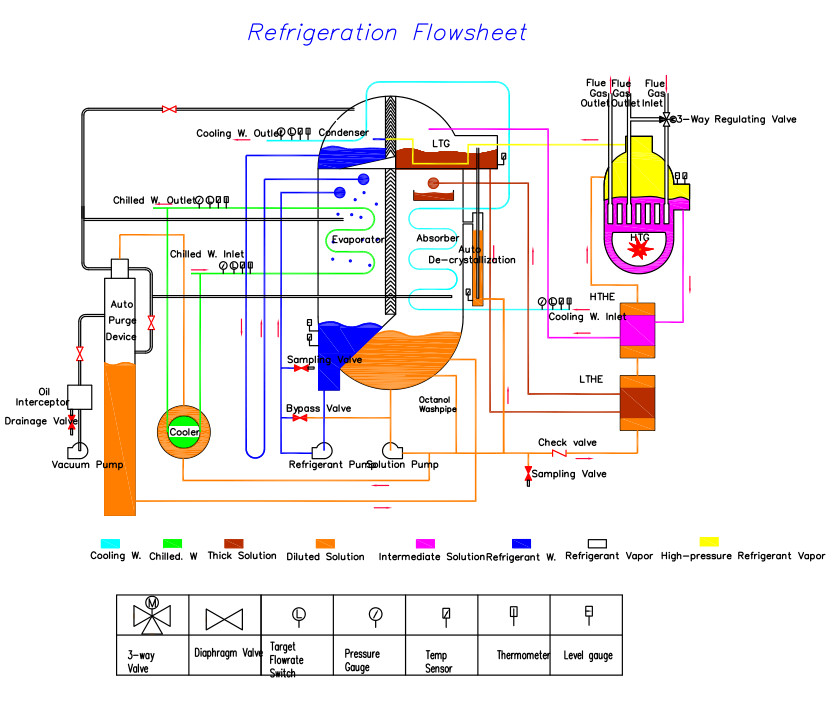

The working principle of the multi-energy LiBr absorption chiller is shown in Figure 2-1. The diluted solution from the absorber, pumped by the solution pump, passes through the low-temperature heat exchanger (LTHE) and high-temperature heat exchanger (HTHE), then enters the high-temperature generator (HTG), where it is boiled by high-temperature flue gas and natural gas to generate high-pressure, high-temperature refrigerant vapor. The diluted solution turns into an intermediate solution. This step is one of the critical functions water chiller manufacturers-Hope Deepblue focus on to enhance performance and energy efficiency.

The intermediate solution flows via HTHE into the low-temperature generator (LTG), where it is heated by the refrigerant vapor from HTG to generate refrigerant vapor. The intermediate solution becomes a concentrated solution. The high-pressure, high-temperature refrigerant vapor generated by HTG, after heating the intermediate solution in LTG, condenses into refrigerant water. The water, after being throttled, together with the refrigerant vapor generated in LTG, enters the condenser and is cooled by the cooling water, turning into refrigerant water.

The refrigerant water generated in the condenser passes through a U-pipe and flows into the evaporator. Part of the refrigerant water vaporizes due to the very low pressure in the evaporator, while the majority of it is driven by the refrigerant pump and sprayed on the evaporator tube bundle. The refrigerant water sprayed on the tube bundle absorbs heat from the water flowing in the tube bundle and vaporizes. In the context of such systems, the expertise of water chiller manufacturers-Hope Deepblue is invaluable in maintaining optimal refrigeration cycles and ensuring energy-efficient performance.

The technology and processes behind these chillers are critical, and water chiller manufacturers-Hope Deepblue continually strive to improve their designs to meet the evolving demands for energy efficiency and sustainability.

The concentrated solution from LTG flows via LTHE into the absorber and is sprayed on the tube bundle. Then, after being cooled by the water flowing in the tube bundle, the concentrated solution absorbs the refrigerant vapor from the evaporator and becomes diluted solution. In this way, the concentrated solution continuously absorbs the refrigerant vapor generated in the evaporator, keeping the evaporation process continuing. In the meantime, the diluted solution is transmitted by the solution pump to HTG, where it is boiled and concentrated again. Thus a cooling cycle is completed by multi energy LiBr absorption chiller and the cycle repeats.