Products

Direct Fired Absorption Chiller

Refrigeration Cycle

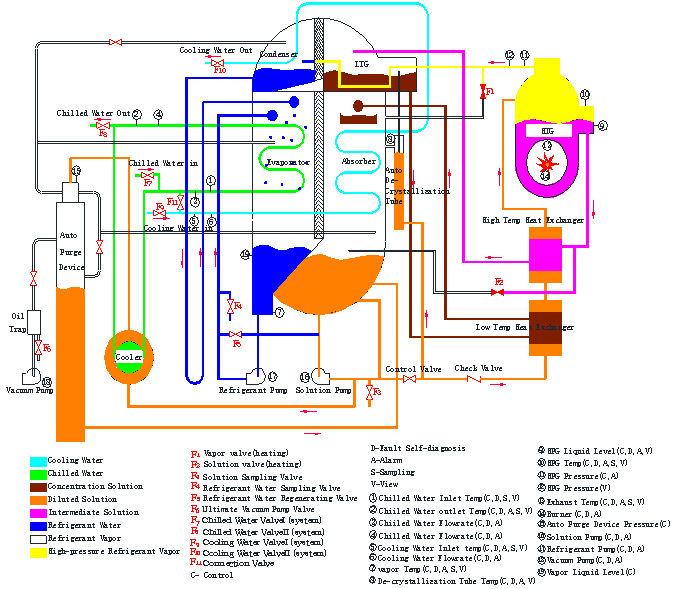

The refrigeration principle of this direct fired absorption chiller (heater) is shown in Figure 1. The heating and cooling switch valve F5 is opened, and F6-F10 are closed. The diluted solution from absorber is transported by the LTG solution pump , and heated by the low-temp heat exchanger and then enters the LTG. In the LTG ,the diluted solution is heated and boiled by the flowing high-pressure and high-temp refrigerant vapor from HTG and the solution is concentrated into an intermediate solution.

Most of the intermediate solution is transported by the HTG solution pump into HTG, after heated by the high-temp heat exchanger. In HTG, the fuel combustion releases heat to heat the LiBr solution to generate high-pressure, high-temp refrigerant vapor, and the solution is further concentrated into concentrated solution.

In the LTG, the high-pressure, high-temp refrigerant vapor from the HTG heats the dilute solution in the LTG and condenses into refrigerant water, which enters the condenser together with the refrigerant vapor generated in the LTG through throttling and depressurization, and then cooled into the refrigerant water corresponding to the condensing pressure by the cooling water in the condenser.

The refrigerant water in the condenser enters the evaporator after being throttled by the U-type tube, and then delivered by the refrigerant pump, sprayed on the evaporator tube cluster, absorbing the heat of the chilled water and evaporating, and then the temperature of the chilled water in the tubes drops, so as to achieve the purpose of refrigeration.

After part of intermediate solution from the LTG mixed with the concentrated solution from the HTG, it flows through the low-temp heat exchanger and enters the absorber, sprays on the absorber tube cluster, and is cooled by the cooling water, and absorbs the refrigerant vapor from the evaporator at the same time and then becomes the diluted solution. The LiBr solution diluted by absorbing the refrigerant vapor in the evaporator is transported into the generator for heating and concentration by the generator pump, which completes a refrigeration cycle. The process is repeated by best direct fired chiller so that the evaporator can continuously produce low-temp chilled water for air conditioning or production process.

Heating Cycle

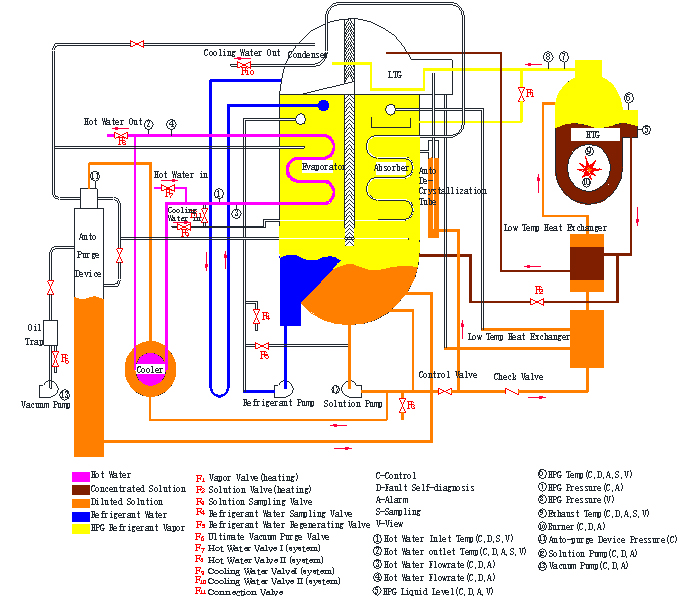

The heating process of the best direct fired chiller (heater) is shown in Figure 2, the heating and cooling switch valves F5, F13, F14 are closed, F6-F10 are opened, the cooling water circuit and the refrigerant water circuit stop running, and the chilled water circuit is converted to a domestic hot water circuit. The Absorber, condenser, LTG, high-temp heat exchanger, low-temp heat exchanger stop working. The diluted solution in absorber is delivered to HTG and concentrated through the solution pump. The generated refrigerant vapor enters the evaporator through the tube and valve F7, condenses on the evaporator tube cluster, and heats the domestic hot water. The condensed refrigerant water enters the absorber from the evaporator water tray through valve F9. The concentrated solution in HTG enters the absorber through valve F8, and is mixed with the refrigerant water in absorber becoming diluted solution. The diluted solution is delivered back to HTG by solution pump and heated. The aforesaid cycle by best direct fired chiller occurs repeatedly to form a continuous heating process.

• Wet-back water-tube HTG: compact structure and high efficiency

Flue gas and solution reverse turbulence heat exchange is sufficient, exhaust temperature ≤170℃.

• Solution reverse series and parallel circulation technology: more full use of heat sources, higher unit efficiency (COP)

The solution reverse series and parallel circulation technology makes the solution concentration of LTG in the middle position, and the concentration of the concentrated solution in HTG is the highest. Before entering the low temperature heat exchanger, solution concentration will reduce after the intermediate solution mixing with concentrated solution. Then best direct fired chiller will obtain a large range for vapor discharge and higher efficiency, also be far away from the crystallization, which is safe and reliable.

• Interlock mechanical&electrical anti-freezing system: multi anti-freezing protection

The coordinated anti-freezing system features following merits: a lowered primary sprayer design for the evaporator,an interlock mechanism which links the secondary sprayer of evaporator with the supply of chilled water and cooling water, a pipe blockage prevention device,a two-hierachy chilled water flow switch, an interlock mechanism designed for the chilled water pump and cooling water pump. Six levels anti freezing design ensures timely detection of break, underflow, low temperature of chilled water, automatic actions will be taken to prevent tube freezing.

• Auto purge system combining multi-ejector&fall- head technology: speedy vacuum purging and high vacuum degree maintenance

This is a new, high efficiency automatic air purge system. The ejector functions as a small air extraction pump. DEEPBLUE automatic air purge system adopts multiple ejectors to increase the air extraction and purge rate of unit. Water head design can help to evaluate vacuum limits and maintain a high vacuum degree. This design can provide a high vacuum degree for every part of unit at any time. Therefore, oxygen corrosion is precluded, service life time is prolonged and optimal operating status is maintained for best direct fired chiller.

• Viable structure design: easy to maintain

Both the absorber solution drop tray and the evaporator refrigerant water nozzle can be disassembled and replaced, to ensure that the cooling capacity does not decrease during the lifespan.

• Automatic anti-crystallization system combining level difference dilution and crystal dissolution: eliminate crystallization

A self-contained temperature&level difference detection system enables unit to monitor excessively high concentration of the concentrated solution. On the one hand upon detecting an overly high concentration the unit will bypass refrigerant water to concentrated solution for dilution. On the other hand, the chiller utilizes HT LiBr solution in generator to heat concentrated solution to a higher temperature. In the event of a sudden power failure or abnormal shutdown, level difference dilution system will start rapidly to dilute LiBr solution and to ensure rapid dilution after power supply recovers.

• Fine separation device: eradicate pollution

The concentration of the LiBr solution in the generator is divided into two stages, the flash generation stage and the generation stage. The real cause of pollution is in the flash generation phase.The fine separation device finely separates the refrigerant vapor with solution in the flash process, so that the pure refrigerant vapor can enter the next step of the refrigeration cycle, eliminating the source of pollution and eradicating the pollution of the refrigerant water.

• Fine flash evaporation device: refrigerant waste heat recovery

The waste heat of the refrigerant water inside the unit is used to heat the diluted LiBr solution to reduce the heat load of the LTG and achieve the purpose of waste heat recovery, energy saving and consumption reduction.

• Economizer: energy output boosting

Isooctanol with a conventional chemical structure as an energy boosting agent added to LiBr solution, is normally an insoluble chemical that has only a limited energy boosting effect. The economizer can prepare mixture of isooctanol and LiBr solution in a special way to guide isooctanol into generation and absorption process, therefore enhancing energy boosting effect, effectively reducing energy consumption and realizing energy efficiency.

• Unique surface treatment for heat exchange tubes: high performance in heat exchanging&less energy consumption

The evaporator and absorber have been hydrophilic treated to ensure even liquid film distribution on tube surface. This design can improve heat exchange effect and lower energy consumption.

• Self-adaptive refrigerant storage unit: improving part load performance and shortening startup/shutdown time

The refrigerant water storage capacity can be automatically adjusted according to external load changes, particularly when unit works under partial load. The adoption of refrigerant storage device can shorten startup/shutdown time substantially and reduce idle work.

• Plate heat exchanger: saving more than 10% energy

A stainless corrugated plate heat exchanger is adopted. This type of plate heat exchanger has a very sound effect, a high heat recovery rate and remarkable energy saving performance. Meanwhile, the stainless steel plate has a service life of over 20 years.

• Integral sintered sight glass: a powerful guarantee for high vacuum performance

The leakage rate of the whole unit is lower than 2.03X10-10 Pa.m3 /S, which is 3 grade higher than national standard, can ensure unit's lifespan.

• Li2MoO4 Corrosion inhibitor: an environment–friendly corrosion inhibitor

Lithium Molybate (Li2MoO4), an environment-friendly corrosion inhibitor, is used to replace Li2CrO4 (Containing heavy metals) during the preparation of LiBr solution.

• Frequency control operation: an energy-saving technology

Unit can adjust its operation automatically and maintain optimal working according to different cooling load.

• Tube broken alarm device

When the heat exchange tubes broke in unit at abnormal condition, control system send out an alarm to remind operator to take actions, reduce damage.

• Super long lifespan design

The designed service life of the whole unit is ≥25 years, reasonable structure design, material selection, high vacuum maintenance and other measures, guarantees the long service life of unit.

• Environmental-friendly combustion type direct fired HTG (optional)

Baet Direct fired Chiller HTG combustion technology adopts the most advanced combustion technology, and all indicators of exhaust emissions meet the most stringent National Environmental Protection Requirements, especially NOx emissions ≤ 30mg/Nm3.

• Fully-automatic control functions

The control system (AI, V5.0) is featured by powerful and complete functions, such as one-key start up/shutdown, timing on/off, mature safety protection system, multiple automatic adjustment, system interlock, expert system, human machine dialogue(multi languages), building automation interfaces, etc.

• Complete unit abnormality self-diagnosis and protection function

The control system (AI, V5.0) features 34 abnormality self-diagnosis&protection functions. Automatic steps will be taken by system according to level of an abnormality. This is intended to prevent accidents, minimize human labor and ensures a sustained, safe and stable operation of chiller.

• Unique load adjustment function

The control system (AI, V5.0) has a unique load adjustment function, which enables automatic adjustment of chiller output according to actual load. This function not only helps to reduce startup/shutdown time and dilution time, but also contributes to less idle work and energy consumption.

• Unique solution circulation volume control technology

The control system (AI, V5.0) employs an innovative ternary control technology to adjust solution circulation volume. Traditionally, only parameters of generator liquid level are used to control of solution circulation volume. This new technology combines merits of concentration&temperature of concentrated solution and liquid level in generator. Meanwhile, an advanced frequency-variable control technology is applied to solution pump to enable unit to achieve an optimal circulated solution volume. This technology improves operating efficiency and reduces startup time and energy consumption.

• Cooling water temperature control technology

The control system (AI, V5.0) can control and adapt the heat source input according to cooling water inlet temperature changes. By maintaining cooling water inlet temperature within 15-34℃, unit operates safely and efficiently.

• Solution concentration control technology

The control system (AI, V5.0) uses a unique concentration control technology to enable real-time monitoring/control of concentration and volume of concentrated solution as well as hot water volume. This system can maintain chiller under safe and stable at high-concentration condition, improve chiller operating efficiency and prevent crystallization.

• Intelligent automatic air purge function

The control system (AI, V5.0) can realize real-time monitoring of vacuum condition and purge out the non-condensable air automatically.

• Unique dilution stop control

This control system (AI, V5.0) can control operation time of different pumps required for dilution operation according to concentrated solution concentration, ambient temperature and remaining refrigerant water volume. Therefore, an optimal concentration can be maintained for the chiller after shutdown. Crystallization is precluded and chiller re-start time is shortened.

• Working parameter management system

Through interface of this control system (AI, V5.0), operator can perform any of following operations for 12 critical parameters relating to chiller performance: real-time display, correction, setting. Records can be kept for historical operation events.

• Unit fault management system

If any prompt of occasional fault is displayed on operation interface, this control system(AI, V5.0) can locate and detail fault, propose a solution or trouble shooting guidance. Classification and statistical analyses of historical faults can be conducted to facilitate maintenance service provided by operators.

Deepblue Remote Monitoring Center collects the data of the units distributed by Deepblue around the world. Through the classification, statistics and analysis of real-time data, it displays in the form of reports, curves, and histograms to achieve an overall overview of equipment operating status and fault information control. Through a series of collection, calculation, control, alarm, early warning, equipment ledger, equipment operation and maintenance information and other functions, as well as customized special analysis and display functions, the remote operation, maintenance, and management needs of the unit are finally realized. The authorized client can browse the WEB or APP, which is convenient and fast.

Load confirmation

Choose the model of the direct fired unit based on the air conditioning or processing cooling load in the building. Check whether its heating capacity can meet the heating load demand. If not, a larger unit is required.

Unit function

According to different application, direct fired unit can be divided into standard type (cooling&heating type), cooling type, and three-purpose type.

Fuel type

There are many types of fuels used in direct fired LiBr absorption unit. Commonly natural gas, coal gas, LPG, light oil, heavy oil and so on. Different heating value results in different burners application. Therefore, before choosing the unit, it is necessary to determine the fuel’s type and heating value. For gas fuel, the gas pressure should be provided as well.

Chilled water outlet temperature

Besides the specified chilled water outlet temperature of a standard unit, other outlet temperature values (min -5℃) may also be selected.

Pressure bearing requirements

The design pressure bearing standard capacity of the chilled water/cooling water system of the unit is 0.8MPa. If the actual pressure of the water system exceeds this standard value, a HP-type unit should be used.

Unit Qty

If more than one unit are used, the unit's QTY should be determined by comprehensive consideration of max load, partial load, maintenance period as well as machine room's size.

Control mode

The standard direct fired LiBr absorption chiller (heater) is supported by an Al (artificial intelligence) control system that enables automatic operation. Meanwhile, there are a number of options available for the customers, such as control interfaces for the chilled water pump, cooling water pump, cooling tower fan interface, building control, centralized control system, IoT access.

Scope of Supply

| Item | Qty | Remarks |

| Main unit | 1 set | LTG, condenser, evaporator, absorber, solution heat exchanger, auto purge device, etc. |

| HTG | I set | Patented technology, high heating efficiency. Three-purpose type can provide domestic water heater. |

| Burner | Including safety devices, filters, etc. | |

| LiBr solution | Adequate | |

| Canned pump | 2/4 set | Different quantity according to difference figuration. |

| Vacuum pump | 1 set | |

| Control system | 1 set | Including sensors&control elements (liquid level, pressure, flow rate and temperature), PLC and touch screen. |

| Frequency converter | 1 set | |

| Commissioning tools | 1 set | Thermometer and common tools. |

| Accompanying accessories | I set | Refer to Packing List, which can meet the demand for 5 years maintenance. |

Model Selection Sheet

| Item | Type | Features | Remarks |

| Function | Standard | Cooling or Heating | |

| Three-purpose | Cooling, heating meanwhile supplying domestic hot water | Heat of domestic hot water need to be specified when ordering. | |

| Cooling | Cooling only | ||

| Fuel | Light oil type | -35~10# light diesel oil | |

| Heavy oil type | Heavy diesel oil, residual oil, mixed oil | Viscosity should be specified when ordering. | |

| Gas type | All All kinds of natural gas, coal gas, LPG | Heat value and pressure should be specified when ordering. | |

| Duel fuel type | Light oil/gas heavy oil/gas | ||

| Special order | HTG enlarged type | Enhance the heating capacity, larger unit, more heating supply | |

| HP type | When the chilled water/cooling water and hot water system pressure≥ 0.8MPa, a high pressure water chamber will be adopted. The pressure bearing capacity may be 0.8-1.6MPa or 1.6-2.0MPa. | ||

| Low grade type | Gas with low heat value or pressure | Heat value and pressure should be specified when ordering. | |

| Vessel-applied type | This type applies to occasions with slight wobbling. Seawater can be used as cooling water. | ||

| Split type | Limited by the size of the user's site, the main body and the HTG can be transported separately. |

Scope of Delivery and Construction

| Items | Description | Scope of Delivery and Construction | Remarks | |

| Deepblue | User | |||

| Unit | Unit and accessories | o | Please refer to Scope of Supply. | |

| Performance test | Ex-factory performance test | o | ||

| Site commissioning | o | One time for cooling and one time for heating | ||

| Transportation to the site | From the factory to the worksite | o | Depends on Sales Contract | |

| From the worksite to the mounting base | o | Depends on Sales Contract | ||

| Installation in place | o | Depends on Sales Contract | ||

| Unit assembly (separate delivery) | o | The user must provide welding equipment, nitrogen and other necessary tools. | ||

| Electrical engineering | Sensors and meters | o | The user must be responsible for laying remote control cables. | |

| External electrical wiring engineering | o | The wires extend till the outlet of the wiring terminal of the control cabinet. | ||

| Other engineering | Foundation construction | o | ||

| External tubing engineering | o | |||

| Air purge system | o | |||

| Tubing system anti-freezing measures | o | During winter shutdowns, please adopt anti-freezing measures for the water tubing. | ||

| Cooling water quality management | o | Please set the cooling water discharge valve or other unit to enable proper water quality management. | ||

| Insulation engineering | o | Optional, depends on Sales Contract. | ||

| Other | LiBr solution | o | ||

| Operation training&instructions | o | |||